2020

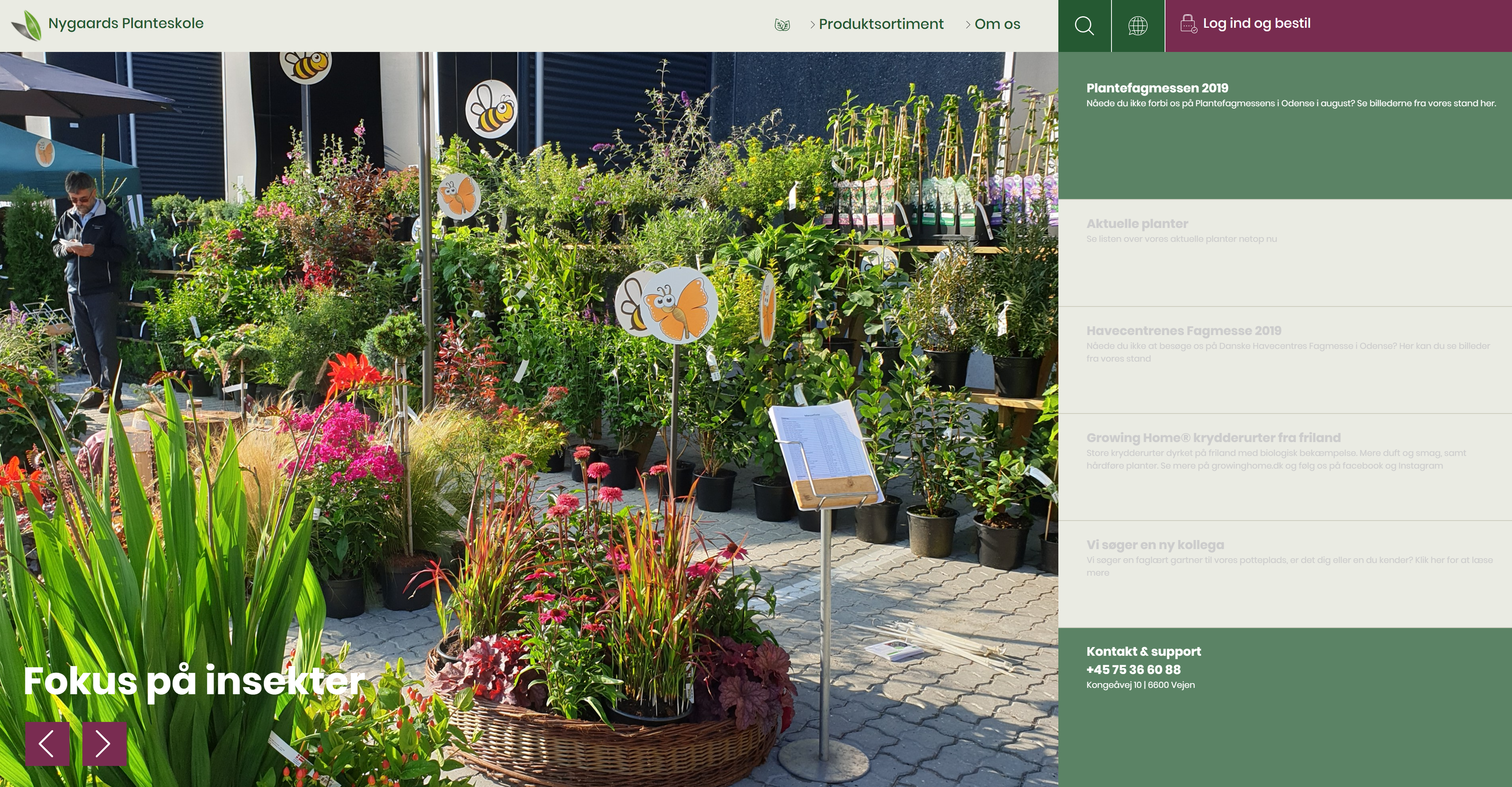

Nygaards Planteskole once again expands on digital initiatives, launching a brand new web platform that focuses even more on ease of use when ordering from PCs, tablets and mobile devices. The website is launched in several languages.

2014

Nygaards Planteskole is 30 years old and a thorough update of the website is being made to ensure that we can continue to be at the forefront with good user-friendly solutions for our customers.

2013

After many years of work and testing, we succeeded in getting our new Yew patented. We celebrated that with a name ceremony at landscaping exhibition Have&Landskab 2013, where Palle Kristoffersen gave the plant its final trade name: Taxus baccata "Brande Select" 'TANY0109' (N) PBR. The test was done in close collaboration with Jørgen Gregersen and Brande Skovkirkegård.

2012

A new and more advanced cutter is being procured for production. This means that the plant is now cut all the way around, rather than just on top, giving a much more uniform and well-branched plant.

2011

Carsten Sølund Kristensen is hired as a new sales consultant. He works with daily sales work, and visits our customers with our show truck.

2010

www.nygaardsplanteskole.dk gets a thorough facelift. The site becomes much more user-friendly for our customers. At the same time, a large number of information is made available to private individuals, who can thus use the website as a source of inspiration.

Malene Nygaard Jensen is hired as marketing coordinator. She works with Nygaards Planteskoles communication to our customers as well as to the end-user and focuses on how we best serve our customers.

The production area is expanded with yet another new greenhouse, replacing the last of the old plastic tunnels.

Root ball production: approx. 13 ha

Container space: approx. 9 ha

Under glass: approx. 26,000 m²

2009

Pernille Ratjen is hired as a new sales consultant. She works with daily sales work, and visits our customers with our show truck.

2008

Nygaards Planteskole decides to significantly expand the production of ground cover plants. Therefore, a Bekidan potter with pot magazine is procured so that we will be able to produce ground cover plants in traditional pots and in the popular 15 pcs trays in the same production line. After 10 years of good cooperation, Erik Lauridsen chooses to seek new challenges.

2007

Nygaards Planteskole expands the production of plants with high impulse value. This is done to meet rising demand.

2005

As the first nursery in Denmark, we invest in a Visser Spaceomat system that ensures a more rational handling of pots. This investment also leads to a halving in SINGLE REPEATING WORK in connection with placing pots on the container site, spacing and cutting plants.

Root ball production: approx. 12.5 ha Container space: approx. 9 ha

Under glass/plastic: approx. 19,000 m²

2004

Nygaards Planteskole is launching a website where it is possible to buy directly online. In the same year, we are expanding both the container space and building two new greenhouses.

Field production: approx. 9 ha

Container space: approx. 9 ha

Under glass/plastic: approx. 19,000 m²

2003

A cooling area of 580 m² is built to ensure more secure wintering, better production management and better utilization of existing facilities.

2002

A further 5,600 m² greenhouse is being built for the production of Magnolia, Hibiscus etc. as well as picking up Laurel and Boxwood grown in the field. These are being potted for wintering under protected conditions in the greenhouses.

Root ball production: approx. 10 ha Container space: approx. 8 ha

Under glass/plastic: approx. 13,000 m²

2001

Root ball production continues to increase and a special tractor is being bought to solve tasks such as root cutting, mechanical and chemical weed control and fertilization.

Root ball production: approx. 8 ha Container space: approx. 8 ha

Under glass/plastic: 7,500 m²

2000

The hurricane in December 1999 has had major consequences for our production facilities, but already in the spring of 2000 a new greenhouse totalling 4,800 m² is ready for use. This allows for a further streamlining of production.

1999

On the 3rd of December Denmark is struck by the worst hurricane in recording. It ravages large parts of the nursery. Most of the tunnel houses are so destroyed that they cannot be reused. It is therefore decided to build a greenhouse.

1998

After several years of good cooperation with Prima Plant, Nygaards Planteskole chooses to stand on its own. Our product range has been considerably expanded, and the desire for closer contact with the garden centres is one of the main reasons for the change. Erik Lauridsen is hired as a sales consultant.

1997

The space in the old expedition hall becomes too small. A 1,000 m² dispatch and storage hall is built, complete with loading ramps and associated office facilities.

1996

The first root ball production is initiated. Production is mainly concentrated on larger plants with Laurel, Boxwood and Mahonia as the main products. Over the next 7 years, the area will be expanded to approx. 10 ha.

1994

The space for container production is greatly expanded by 32,500 m2 and the first large irrigation booms are procured. The basic framework for large-scale production is now laid.

1992

Nygaards Planteskole, together with 3 other Danish nurseries, establishes the sales company Prima Plant. This step should allow the nursery to concentrate on production and product development while Prima Plant is responsible for sales.

1991

Bente Juul Jensen resigns from Plantedirektoratet, plant health checks under the Danish Ministry of Agriculture, and is employed full time in the nursery.

1988

The production area is now significantly expanded and investments are made in a potting machine for more rational production. Production is gradually converted to finished plants.

1986

The company's first computer system is put into operation. 2 PCs, model 386 SX 25 Mhz with 4 Mb Ram + printer etc. Total price: approx. DKK 80,000 has since been replaced. Additional tunnel houses are built in the same year.

1984

Nygaards Planteskole is founded. The nursery is established on a former agricultural property. The first tunnel houses are erected and the first production is started. Plants are mainly produced for further culture.

Product prices are converted and displayed based on the current exchange rate for the selected currency

Much has changed since Bente and Søren bought a abandoned agricultural property outside the town of Vejen in the spring of 1984. Here they established Nygaards Planteskole, which today is one of the country's largest nursery with plants for gardens and landscaping. The focus is, and always has been, on innovation, quality and efficiency.